tyler pipe fitting book pdf

The Tyler Pipe Fitting Book is a comprehensive guide for professionals, offering detailed insights into cast iron pipe systems, installation, safety, and compliance with industry standards like CISPI 310. It serves as an essential resource for mastering pipe fitting techniques and ensuring reliable system performance.

Key Chapters in the Tyler Pipe Fitting Book

The book covers essential chapters, including hubless cast iron pipes, shielded couplings, CISPI 310 standards, and hydrostatic testing. Each chapter provides detailed guidance for professionals working with pipe fitting systems.

2.1. Chapter 1: Overview of Pipe Fittings

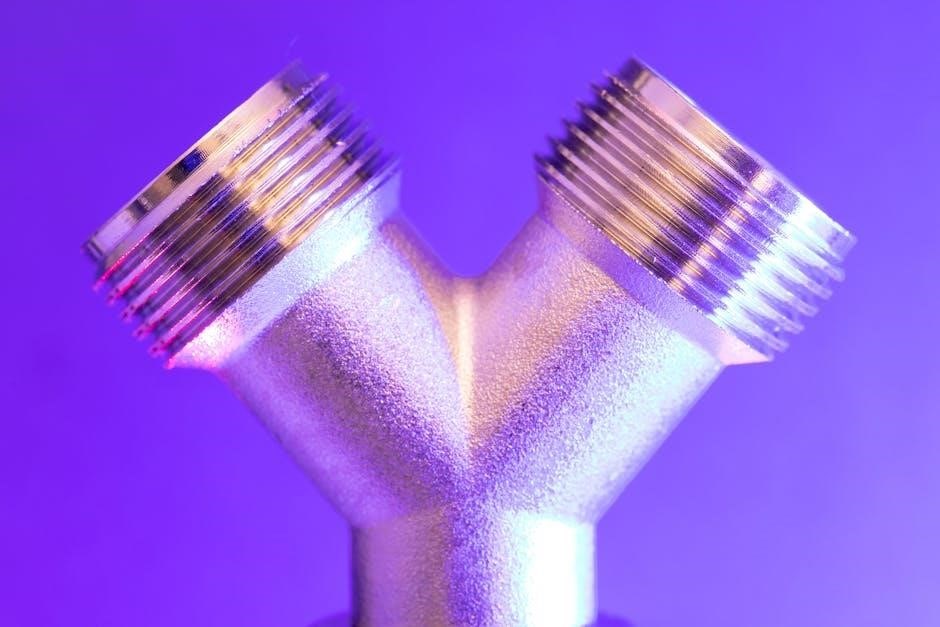

Chapter 1 provides a foundational understanding of pipe fittings, their functions, and applications. It introduces the basic types of fittings, such as couplings, bends, and tees, explaining their roles in connecting and directing pipe systems. The chapter also covers the importance of material selection, including cast iron, ductile iron, and other alloys, ensuring compatibility with various plumbing and industrial systems. Key topics include the classification of fittings based on their connection methods, such as threaded, flanged, or hubless designs, and their suitability for different environments. Additionally, the chapter highlights industry standards like CISPI 310, which govern the manufacturing and performance of pipe fittings. This overview serves as a starting point for professionals to understand the fundamentals of pipe fitting systems, preparing them for more detailed chapters ahead. By focusing on core concepts, Chapter 1 sets the stage for mastering the specifics of pipe fitting installation, safety, and compliance.

2.2. Chapter 2: Types of Pipes and Fittings

Chapter 2 delves into the diverse range of pipes and fittings, categorizing them based on their materials, shapes, and connection methods. It emphasizes the importance of selecting the right components for specific applications, ensuring system durability and performance. The chapter discusses hubless cast iron pipes, a popular choice for underground installations due to their corrosion resistance and strength. Shielded couplings, which provide leak-proof connections, are also highlighted as essential for maintaining system integrity. Additionally, the chapter explores various fitting types, such as bends, tees, and reducers, explaining their roles in directing and controlling fluid flow. By focusing on the unique characteristics and uses of each pipe and fitting, this section equips readers with the knowledge to make informed decisions for their projects. The detailed descriptions and specifications provided ensure compatibility with industry standards like CISPI 310, making this chapter a vital resource for professionals working with pipe systems.

Installation and Assembly Guidelines

Chapter 3 provides detailed instructions for the proper installation and assembly of Tyler Pipe products, ensuring a secure and durable connection. It emphasizes the importance of following manufacturer guidelines to prevent leaks and system failures. The section highlights the use of shielded couplings for hubless cast iron pipes, as recommended by CISPI 310 standards, to ensure leak-proof joints. Instructions include aligning the pipe straight with the fitting socket and tightening the nuts on T-head bolts gradually. The chapter also advises against testing cast iron pipes with compressed air or gas, stressing the importance of hydrostatic testing as described in the CISPI handbook. Additional tips cover selecting the right fittings for specific applications, measuring bends and branches accurately, and maintaining proper alignment during installation. These guidelines are designed to help professionals achieve reliable and long-lasting pipe systems, whether for above-grade or underground applications. Adhering to these steps ensures compliance with industry standards and optimal system performance.

Safety Recommendations and Best Practices

Chapter 4 emphasizes the critical importance of safety and best practices when handling and installing Tyler Pipe products. It underscores the need to avoid using compressed air or gas for testing cast iron pipes and fittings, as this can lead to catastrophic failures. Instead, hydrostatic testing is recommended, following the guidelines outlined in the CISPI handbook. The section also highlights the importance of proper handling to prevent damage to the pipe and fittings, as well as ensuring a safe working environment. It advises against using incompatible materials with Tyler Pipe products, as this could compromise system integrity. The chapter provides detailed safety protocols for each stage of installation, from preparation to final testing, ensuring that all industry standards are met. By adhering to these recommendations, professionals can minimize risks, protect their teams, and ensure the reliability and longevity of the piping system. These best practices are essential for maintaining a safe and efficient installation process.

Hubless Cast Iron Pipes and Fittings

Hubless cast iron pipes and fittings are a popular choice for their durability and ease of installation. The Tyler Pipe Fitting Book provides detailed guidance on the use of these systems, emphasizing their compatibility with shielded couplings manufactured in accordance with CISPI 310 standards. These couplings ensure a secure and leak-proof connection, making them ideal for both above-grade and below-grade applications. The book highlights the versatility of hubless systems, which can be used in soil, waste, and storm drainage systems. It also discusses the importance of proper alignment and deflection values to maintain system integrity. The section covers the measurement of long fittings, including bends and branch fittings, to ensure accurate installations. By following the recommendations in this chapter, professionals can achieve reliable and long-lasting pipe connections, adhering to industry standards and best practices. This makes hubless cast iron pipes and fittings a preferred option for numerous plumbing and piping projects.

Shielded Couplings and Their Importance

Shielded couplings play a vital role in ensuring the integrity and reliability of pipe connections, particularly in hubless cast iron systems. The Tyler Pipe Fitting Book emphasizes their importance in preventing leakage and protecting against environmental factors that could compromise the system. These couplings are specifically designed to provide a secure and durable connection, making them essential for both above-grade and underground installations. Tyler Pipe strongly recommends using shielded couplings that meet CISPI 310 standards to guarantee optimal performance and compliance with industry regulations. Proper installation of these couplings is critical, as they protect the pipe joints from damage and ensure long-term system reliability. The book provides detailed guidance on selecting and installing shielded couplings, highlighting their significance in maintaining the structural integrity of cast iron pipe systems. By adhering to these guidelines, professionals can ensure safe and efficient piping solutions for a wide range of applications. Shielded couplings are a cornerstone of modern pipe fitting practices.

CISPI 310 Standards for Pipe Fittings

The CISPI 310 standard is a critical guideline for the manufacture and testing of cast iron pipe fittings, ensuring they meet rigorous quality and performance requirements. Tyler Pipe emphasizes the importance of adhering to these standards, particularly for hubless cast iron pipes and shielded couplings. CISPI 310 specifies detailed criteria for materials, dimensions, and testing procedures, ensuring fittings are durable and reliable. The standard also addresses the compatibility of fittings with various pipe types and their suitability for different applications. By complying with CISPI 310, Tyler Pipe guarantees that its products meet industry benchmarks for safety and efficiency. The book provides insights into how these standards are applied in real-world scenarios, helping professionals understand their role in maintaining system integrity. Adherence to CISPI 310 is non-negotiable for achieving long-lasting and leak-free pipe connections, making it a cornerstone of modern pipe fitting practices. This section is essential for anyone involved in the specification or installation of cast iron pipe systems.

Warranty Policies and Manufacturer Guidelines

Tyler Pipe’s warranty policies are designed to ensure the quality and durability of their pipe and fitting products. The manufacturer strictly outlines that its hubless cast iron pipes and fittings must be used exclusively with Tyler Pipe products to maintain warranty validity. Mixing with other manufacturers’ components is explicitly prohibited. The book provides detailed guidelines on proper installation, maintenance, and usage to avoid voiding the warranty. It emphasizes the importance of adhering to these recommendations to ensure optimal performance and longevity of the piping systems. The warranty covers defects in materials and workmanship, offering replacements or repairs as needed. By following the manufacturer’s guidelines, users can ensure compliance and maximize the lifespan of their pipe fittings. This section is vital for understanding the terms and conditions of Tyler Pipe’s warranty, ensuring customers can rely on their products for long-term reliability and performance. Proper adherence to these policies is crucial for maintaining system integrity and avoiding potential issues down the line.

Ordering and Specification Guide

This section provides a detailed guide for ordering and specifying Tyler Pipe products, ensuring clarity and accuracy in the selection process. It outlines essential steps for choosing the right pipe and fitting configurations, including size, material, and coatings. The guide emphasizes the importance of adhering to CISPI standards and manufacturer recommendations to ensure compatibility and system performance. Key considerations such as measurement guidelines, fitting types, and accessory requirements are also covered. By following this guide, users can streamline the ordering process, reduce errors, and ensure that their specifications meet project requirements. Proper ordering practices are crucial for maintaining system integrity and avoiding delays. This section is particularly useful for contractors, engineers, and specifiers seeking to optimize their piping systems. The guide also includes examples of how to interpret product catalogs and technical documentation effectively. Adhering to these guidelines ensures that all components are delivered to the job site correctly and efficiently. This comprehensive approach simplifies the ordering process, saving time and resources.

Hydrostatic Testing Procedures

Hydrostatic testing is a critical procedure for ensuring the integrity of pipe systems, as outlined in the Tyler Pipe Fitting Book. This section provides detailed steps for conducting hydrostatic tests safely and effectively. It emphasizes the importance of using water, not compressed air or gas, to pressurize the system, aligning with CISPI standards. The recommended test pressure and duration are specified to verify the strength and leak-tightness of pipes and fittings. Pre-test preparations, such as ensuring all connections are secure and systems are properly vented, are highlighted. The section also covers post-test inspections to identify and address any issues. Proper documentation of test results is stressed for compliance and record-keeping. Following these guidelines ensures system reliability and safety. This procedure is essential for contractors and engineers to validate pipe installations before they are put into service. Adhering to these steps minimizes risks and guarantees a durable piping system.

Resources for Further Learning

The Tyler Pipe Fitting Book directs readers to additional resources for deeper understanding of pipe fitting principles and practices. It recommends downloading the Cast Iron Soil Pipe Fittings and Couplings Catalogue in PDF format for detailed product specifications. The CISPI Handbook is highlighted as a key reference for industry standards, particularly CISPI 310, ensuring compliance with best practices. For hands-on learners, the Pipe Fitters Handbook and Level 1 Fundamentals of Pipe Fitting are suggested for practical guidance. Online platforms like Perlego offer access to academic and non-fiction books, including those on pipe fitting. The book also points to Tyler Pipe Company’s official resources, such as warranty policies and installation guides, to support professionals in their work. These resources collectively provide a comprehensive learning path for engineers, contractors, and students seeking to master pipe fitting techniques and stay updated on industry developments.

Leave a Reply

You must be logged in to post a comment.